In going from careful use of floppy disks to now regularly filling terabyte SSDs to capacity with a...

Safety Always - A Review on Safety in 2024

Through its 35 years of company history, BDI has always prioritized the importance of safety in its culture and work. As the company has grown over the years, the importance of managing and implementing a safety program across BDI’s offices as well as our teams in the field across the country was a high priority for CEO Darwin Nelson. In April 2024, BDI demonstrated its commitment to safety by hiring its first Director of Health, Safety and Environment (HSE), with the goal of creating a formal HSE program designed to result in excellence above and beyond regulatory compliance.

Mr. Michael Saks, CHST, with nearly 25 years of experience in HSE management in the construction, energy and manufacturing settings joined BDI to serve this important role. Mr. Saks has extensive experience in Quality Control and Process Management, providing support to BDI’s field teams in their endeavor to deliver our clients the highest-quality work, in a safe and efficient manner.

Mr. Saks began his tenure at BDI by visiting our teams in the field to understand the nature and settings of our work. Viewing work at heights and workers exposed to vehicular traffic as our biggest exposures, BDI focused on improving the management of hazards associated with those areas of work.

Working from HeightsBDI ensures that fall hazards are adequately addressed by revising the Job Hazard Analysis (JHA) development and review process. BDI’s Site Supervisor prepares the JHA then meets with the Director of HSE to review and modify as necessary before submitting to our project Client for their review and recommendations based on site specific experience. This includes a review of types of fall protection to be implemented, adequacy of anchorages, and proper use and inspection of personal fall arrest gear.

Additionally, BDI provided refresher Fall Hazard Awareness training to all employees who are required to wear or use fall arrest equipment in the performance of their work.

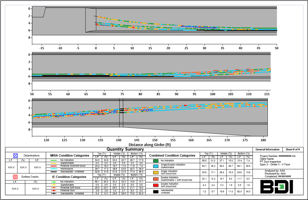

Exposure to Vehicular Traffic – SOUNDAR Deck Testing

BDI evaluated every task associated with the work we conduct while performing inspections on bridge decks and implemented numerous changes to equipment (including modifications to the SOUNDAR van itself), processes, and PPE. BDI eliminated “live lane exposure” by ensuring that the crew member assigned to deploy the SOUNDAR equipment exited the van from the “dead” lane. BDI also implemented Class E reflective pants for all workers working in traffic-controlled work zones from 30 minutes before sundown to 30 minutes after sunrise.

Reflection on 2024

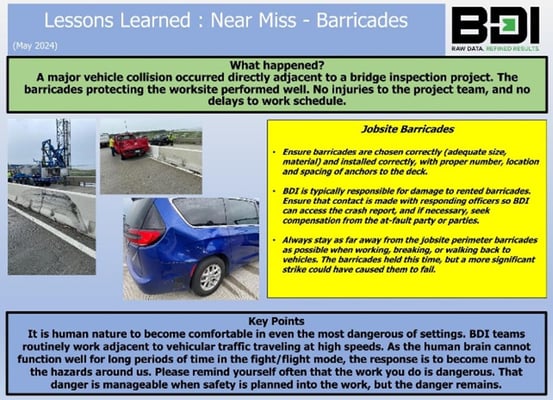

BDI understands that incidents, near-misses, and opportunities for improvement inevitably occur. When they do, their only value is to serve as Lessons Learned to minimize the frequency of severity of future occurrences. To this end, BDI implemented the company wide distribution of Lessons Learned and encourages all employees to communicate with the Director of HSE when they see room for improvement in the BDI HSE Program.

Results:

BDI is proud to share that in 2024, in the performance of nearly 180,000 hours of work performed in hazardous conditions, BDI employees sustained ZERO recordable injuries.

| BDI 2024 Total Recordable Injuries: | 0 |

| BDI 2024 Total Recordable Injury Rate: | 0.0 |

BDI is dedicated to viewing our 2024 HSE performance as a springboard and will continue to examine every project, and every task with the goal of finding a safer, and more efficient way to do it.